- PRODUCTS

- MODEL LIST

- APPLICATIONS

- SUPPORT

- SALES/SERVICE

- BLOG

- ABOUT

Radiometer Calibration Transfer

The functionality on this page was blocked because content blocking is enabled.

Please use another browser to access the form. We recommend Google Chrome. [Learn More]

Establishing a New Calibration Facility in Philomath, Oregon

September 2018

Introduction

In May 2018, Sea-Bird Scientific’s facility in Halifax, Nova Scotia (formerly Satlantic) officially closed its doors. For all manufacturing and operations in Halifax, 2017 involved a heavy lift to transfer inordinate amounts of knowledge, expertise, processes, and equipment to Sea-Bird Scientific’s facilities in Bellevue, Washington and Philomath, Oregon. Among those was the transfer of production and calibration of radiometers.

Philomath, the former WET Labs facility, was a natural choice to adopt radiometer calibration; the manufacturer of several optical sensors (including the ECO PAR sensor, jointly developed by WET Labs and Satlantic), the staff and facilities in Philomath were already geared towards calibrating optical sensors. With a one-year overlap, the two facilities leveraged shared knowledge to replicate and improve calibration procedures during the transfer, applying the rigorous scientific principles at the heart of the radiometer product line to the new calibration lab.

The Halifax calibration facility acted as the baseline for calibration quality, having already established itself as a trusted facility by lab intercomparisons in the past: NASA’s Seventh SeaWIFS Intercalibration Round-Robin Experiment (SIRREX-7, Hooker et al. 2002), conducted in 1999, compared Halifax to the Center for Hydro-Optics and Remote Sensing (CHORS, San Diego State University, California, USA) and the Joint Research Centre (JRC, Ispra, Italy). More recently, Sea-Bird Scientific participated in the European Space Agency (ESA) sponsored Fiducial Reference Measurements for Satellite Ocean Colour (FRM4SOC) program. Throughout the transfer, this proven calibration quality in Halifax continuously vetted the development of the calibration labs in Philomath. Meanwhile, on the other end of North America, the Philomath lab represented a new beginning for radiometer calibration—a chance to replicate and expand on existing procedures—and the opportunity to overcome old and new challenges.

The Calibration Laboratory

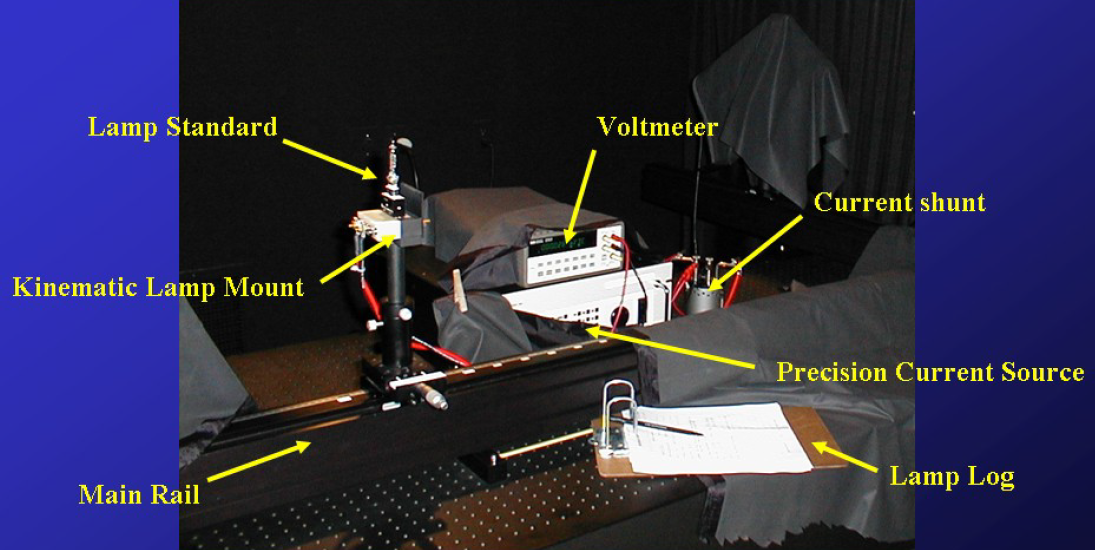

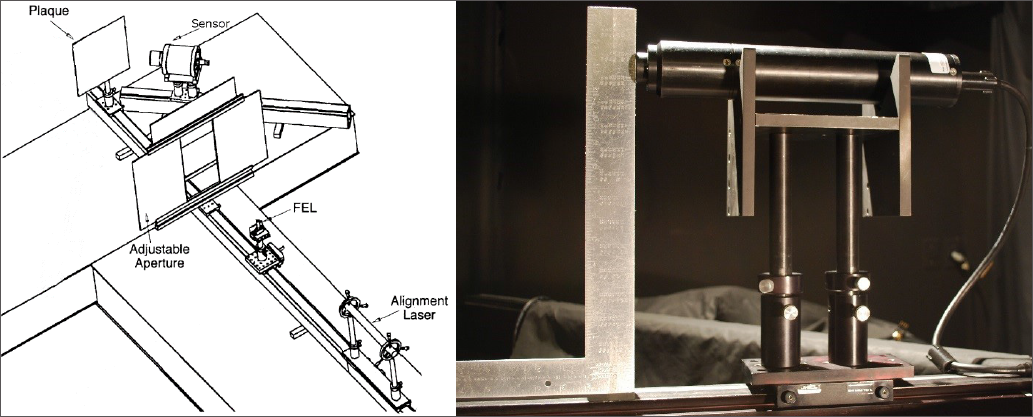

The calibration facilities are similar in design—they utilize almost identical equipment and geometry to produce comparable calibration quality and repeatability. The labs are temperature and humidity controlled, and stay under positive pressure to minimize dust entering the rooms. Sticky mats and booties help maintain a clean working environment and reduce dust that would otherwise scatter light. Curtains enclose the entire calibration setup. All walls, equipment, and furniture are painted ultra matte black or enclosed in black fabric to minimize stray light.

The Philomath lab uses identical equipment to the Halifax lab:

- FEL irradiance standards and power supplies from Gooch and Housego (Optronic Labs)

- 18-inch square Spectralon plaques manufactured by Labsphere

- A precision 0.01 ohm shunt used in series with the lamp

- A multimeter to monitor lamp voltage

- Specific mounts and rails for establishing fixed sensor/lamp positions

Note: All equipment receives NIST-traceable calibrations.

Sensors are mounted in V-blocks pre-set to the height required for various sensors. Alignment is achieved using a laser, located well behind the lamp, and a lamp alignment jig with precision crosshairs on a glass surface. Front surface mirrors placed on the front of sensors and plaque reflect the laser back onto itself. Sensor position is measured from the front surface using a square and a ruler that is part of the rail assembly. Offsets between lamp electrodes and the carrier base, and between the plaque surface and its carrier base, are performed by averaging multiple measurements made with calibrated calipers.

Once installed in the fixture, the calibration procedure involves aligning the sensor, installing the lamp, allowing the lamp to warm up for 20 minutes, then collecting data for 3-5 minutes. Lamp voltage and current are noted before and after calibration to identify changes to the lamp, and software monitors for changes in sensor integration time, sensor temperature swings, excessive noise, poor dark readings, etc. After calibration, sensors are compared to outdoor reference sensors as an additional reality check.

The process of revisiting the familiar calibration procedure in a new environment offered new analysis opportunities; metadata such as lamp voltage and room temperature recorded alongside sensor output granted fresh insight into error sources in calibration quality. The result: Philomath, a growing, improving successor to the calibration labs in Halifax.

Comparison Methods

Two primary metrics determined the quality of calibrations in Philomath compared to calibrations in Halifax:

- Comparisons of calibration repeatability at each site. Repeatability of subsequent calibrations (of both the same sensor and of varying sensors) determined uncertainty in the calibration method, process, and equipment. Experimental results were compared with values calculated from uncertainty tables for the calibration equipment.

- Average of the calibrations, comparing calibration data from individual sensors obtained at each site. This provides statistics for each site and between sites. Using the average of the calibrations at each site for the comparison, reduces the effects of repeatability specific to the site.

In total, ten reference sensors were used to obtain comparison data. For each reference sensor, four calibrations were performed at each site for intercomparison data. These included the following sensors:

- Four OCR-507 multispectral irradiance sensors

- Two OCR-507 multispectral radiance sensors

- Two HyperOCR hyperspectral irradiance sensors

- Two HyperOCRs hyperspectral radiance sensors

Evaluations were conducted with the same lamp, power supply, and plaque at each site for the Hyperspectral sensor calibrations. Multispectral sensor calibrations mostly used a different lamp, power supply, and plaque at each site, though some calibrations were conducted with the same equipment. Using varying equipment provided assessment of lamp and plaque uncertainties for consideration when comparing calibrations.

In addition to the reference sensors, the verification process included several sensors manufactured, calibrated, and tested in Philomath to ensure that full production procedures are properly implemented. These “production sensors” included PAR sensors, OCR-504s, OCR 507s, and HyperOCRs.

Results

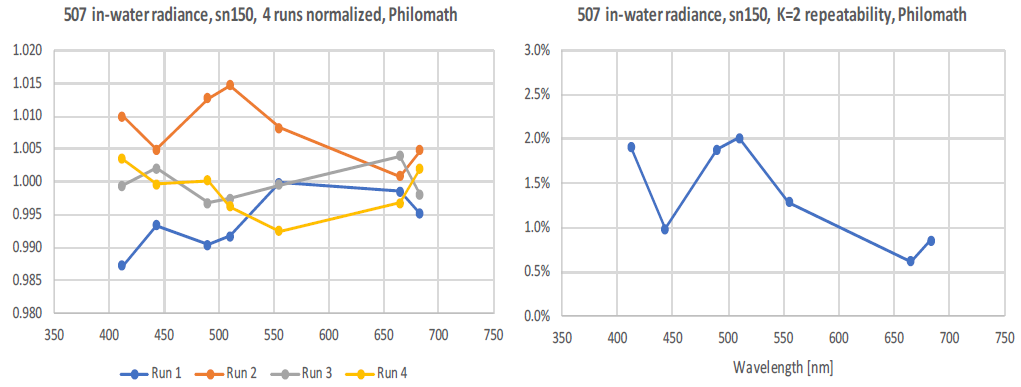

Four early calibrations conducted over the course of the year yielded high uncertainty barely within the expected tolerance (Fig 3). These calibrations occurred outside of the regular calibration procedure, so are not representative of the final quality of Philomath calibrations: they were far apart in time and data were obtained with changing calibration equipment, which does not accurately reflect the true calibration procedure for sensors in production.

Compared to the calibration results from the same reference sensor in Halifax, the uncertainty from these early Philomath calibrations was significantly higher (around 2%, k=2). However, the calibrations in Halifax were conducted in the already established laboratory, using the standard calibration procedures applied to sensors in production (Fig 4).

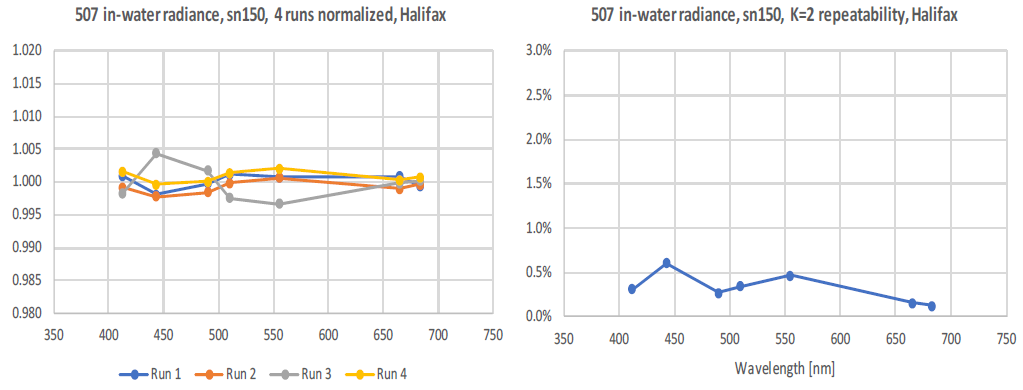

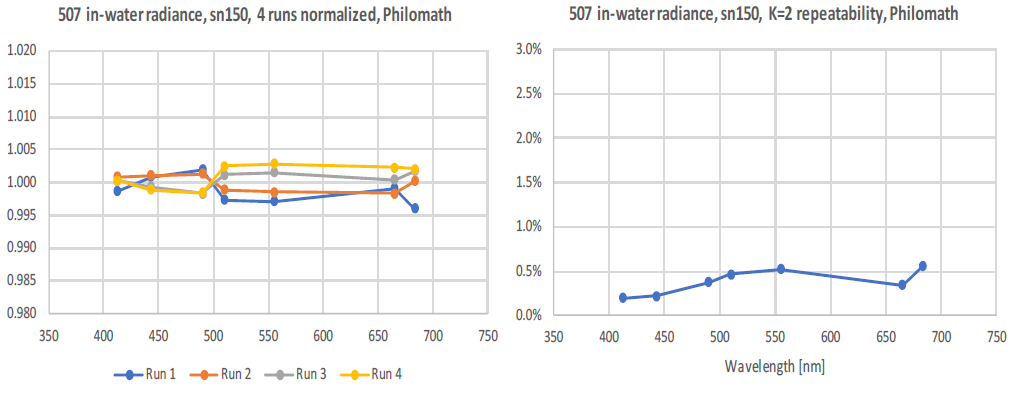

Using the Halifax results and methods as a baseline, the first high-uncertainty calibrations from Philomath were conducted in conditions that don’t reflect the true calibration facility and procedures. Repeating four successive calibrations in Philomath, with the same calibration equipment and more tightly grouped in time, provided results that met or exceeded the uncertainty obtained in Halifax (Fig 5).

| Sensor | Source | 350 nm | 500 nm | 650 nm | 800 nm |

| Both | NIST FEL, k=1 | 0.65 | 0.4 | 0.35 | 0.30 |

| Both | G&H FEL additional, k=1 | 0.5 | 0.5 | 0.5 | 0.5 |

| Both | Lamp aging, 50 h, k=1 | 0.29 | 0.29 | 0.29 | 0.29 |

| Both | Power supply, k=1 | 0.045 | 0.02 | 0.02 | 0.015 |

| Both | Lamp alignment, k=1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Both | Thermal responsivity, k=1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Radiance | Lamp optical center, k=1 | 0.07 | 0.07 | 0.07 | 0.07 |

| Radiance | Plaque 0/45 reflectance, k=1 | 1.0 | 0.8 | 0.8 | 1.5 |

| Radiance | Lamp-plaque distance, k=1 | 0.06 | 0.06 | 0.06 | 0.06 |

| Radiance | Plaque alignment, k=1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Radiance | Sensor angular alignment, k=1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Radiance | Lamp-sensor distance, k=1 | 0.16 | 0.16 | 0.16 | 0.16 |

| Radiance | Sensor angular alignment, k=1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Total Expanded Uncertainty (k=2): Irradiance | 1.8 | 1.5 | 1.4 | 1.4 | |

| Total Expanded Uncertainty (k=2): Radiance | 2.7 | 2.2 | 2.2 | 3.3 | |

Table 1: Sources of repeatability uncertainty between the Halifax and Philomath calibration labs using varying equipment. These figures represent factors that introduce uncertainty between each lab, not absolute uncertainty for final radiometer calibration. Figures are provided by the equipment manufacturer or from literature (see References). Lamp aging is discussed Bernhard and Seckmeyer (1999), with a minimum of 0.01%/hour. Sea-Bird uses lamps for up to 50 hours (uncertainty=(0.01%/hr)*(50hr)/(√3) = 0.29%.)

These results ring true for the other reference sensors. Overall, final calibrations of multispectral radiance, multispectral irradiance, hyperspectral radiance, and hyperspectral irradiance sensors met the target goal of 2% expanded uncertainty (k=2). This 2% goal was established based on expected uncertainty from the calibration equipment and geometry, as reported by the manufacturer of the calibration equipment and through literature (Table 1). Final results show no clear biases at either facility.

Conclusion

Now that the dedicated radiometer calibration lab in Philomath is meeting the target calibration goals, participation in other lab intercomparisons will help elevate the Philomath facility to the same status achieved by the Satlantic. Furthermore, continuous analysis of calibration data will help maintain and improve upon radiometer calibration quality to surpass the quality achieved in Halifax.

The intercomparison represented a rare opportunity to compare two radiometer calibration labs in detail. The results show that Philomath is maintaining quality for radiometer calibrations with the added opportunity to improve upon existing procedures. Leveraging the expertise of the Halifax lab, we were able to identify sources of error and collect metadata while establishing the Philomath lab. Without that year-long overlap of the Halifax and Philomath calibration labs, meeting the Satlantic calibration quality would have been extremely difficult; we benefited from continuous support and expertise from Satlantic’s already established and respected facility.

References

Hooker, Stanford B.; Firestone, Elaine; Mclean, Scott; Sherman, Jennifer; Small, Mark; Lazin, Gordana; Zibordi, Giuseppe; Brown, James; McClain, Charles (2002) The Seventh SeaWiFS Intercalibration Round-Robin Experiment (SIRREX-7), March 1999.

Yoon, Howard W.; Gibson, Charles E. (2011) Spectral Irradiance Calibrations. Special Publication (NIST SP) - 250-89, July 2011.

Bernhard, G.; Seckmeyer, G. (1999) Uncertainty of measurements of spectral solar UV irradiance. Journal of Geophysical Research, vol. 104, no. D12, pg. 14321-14345.

Kuusk, Joel; Ansko, Ilmar; Vabson, Viktor; Ligi, Martin; Vendt, Riho (2017) Protocols and Procedures to Verify the Performance of Fiducial Reference Measurement (FRM) Field Ocean Colour Radiometers (OCR) used for Satellite Validation. ESA, FRM4SOC-TR5, D-130 Technical Report TR-5, version 1.2, 60 pgs.